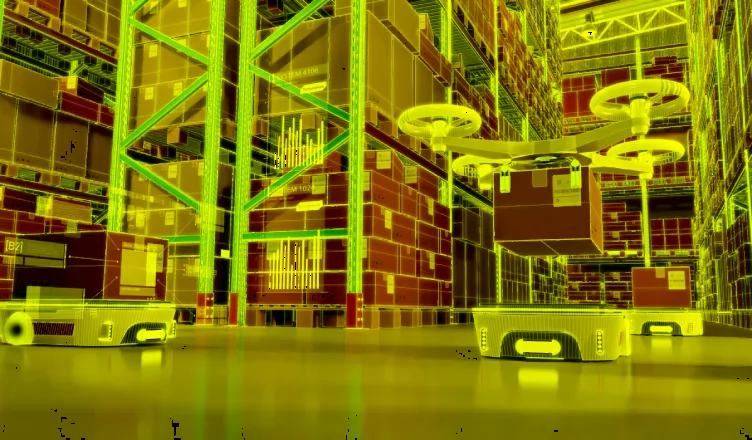

Efficient logistics and warehouse management are critical to the success of modern businesses. With surging e-commerce demands, faster delivery expectations, and tighter margins, companies are turning to robotics in warehouseoperate. Robotics is not only reshaping supply chains but is also setting the stage for the future of logistics, offering efficiency, precision, and cost savings.

This blog explores the sweeping benefits of robotics in warehouse management to demonstrate how it’s becoming an indispensable part of logistics operations.

Increased Efficiency

One of the most remarkable benefits of robotics in warehouses is the significant boost to efficiency. Robots can handle repetitive tasks like picking, packing, sorting, and palletizing far more effectively than human workers. According to a recent report by McKinsey, automated warehouses can increase overall operational efficiency by up to 30%.

Additionally, robots operate 24/7 without breaks or fatigue, drastically reducing downtimes. This enhanced productivity positions businesses to meet the growing expectations of same-day and next-day deliveries in the e-commerce sector.

Precision and Accuracy

Manual processes often leave room for human errors in picking, packing, and inventory management. Even a minor error can lead to customer dissatisfaction and affect business reputation. Robotics offers unmatched precision and accuracy, ensuring error-free operations.

For example, robots equipped with AI sensors can identify correct items and pack them with millimeter accuracy. According to a study by Research and Markets, implementing robotic picking systems can reduce picking errors by more than 70%, translating into cost savings and improved customer satisfaction.

Cost Reduction

Although introducing robotics into warehouse operations requires an upfront investment, the long-term cost benefits are undeniable. Robotics reduces labor costs, minimizes wastage, and optimizes storage space. Automated systems also allow for smaller, high-density storage spaces, saving on real estate costs.

Deloitte’s logistics report highlighted that companies deploying fully automated warehouses could see cost reductions of up to 40%, making robotics a financially viable solution.

Improved Safety

Warehouse workers often face safety challenges, especially when dealing with heavy loads, repetitive movements, or hazardous materials. Robotics minimizes these risks by handling physically demanding and dangerous tasks, creating a safer work environment for employees.

Collaborative robots, or “cobots,” work alongside humans to lift heavy items and automate repetitive movements, significantly reducing workplace injuries. A report by the Bureau of Labor Statistics shows that robotic assistance can help cut workplace injuries related to repetitive movements by over 25%.

Real-Time Data and Analytics

Robotic systems are increasingly equipped with data collection and analysis capabilities, enabling warehouses to operate more intelligently. With real-time monitoring, businesses can gain insights into inventory levels, streamline workflows, and forecast demand more accurately.

According to Gartner, companies that integrate robotics with data analytics can see an improvement of up to 20% in supply chain optimization, helping them stay ahead in competitive markets.

Sustainability

Logistics plays an essential role in companies’ sustainability goals. Robots in warehouses can reduce energy consumption by optimizing workflows and using energy-efficient technologies. For instance, autonomous mobile robots (AMRs) plan shorter paths and minimize wasteful movement, contributing to a greener supply chain.

A report by World Economic Forum goes on to estimate that sustainable robotics in logistics could help reduce carbon emissions by 50,000 tons per year across industries.

A Glimpse Into the Robotic Revolution

The integration of robotics into warehouse management is not a distant future—it’s here and growing rapidly. Businesses that adopt robotic technologies are unlocking unprecedented efficiency, minimizing costs, and staying agile in a competitive marketplace.